Need a prop?

Not sure which one?

Please read our prop selection guide below. It has all the info you will need to select the right prop!

The basics:

1: Pitch

Pitch is the measurement that defines most prop selections. The pitch is effectively the gearing of the boat. Pitch is the effective distance a prop would travel in one rotation through the water. This means a 10" pitch prop would travel 10" through the water if it was spun one revolution. Pitch is still measured in inches, so when you see the pitch number, such as 15, that means that prop has a 15" pitch. A higher pitch means more forward thrust, a lower pitch means less forward thrust. High pitch props generally have a severely raked blade, whereas low pitch props normally have a mildly raked blade. Low pitch props help takeoff, at the expense of top speed. High pitch props can kill takeoff, but give you great top speed if you have the HP to drive the prop.

2: Diameter

Diameter is something that is important when considering a prop for your boat, but it doesnt dictate what prop is correct for your boat the way pitch does. Generally, as the size and HP of your motor increases, so does the diameter. A large diameter prop will normally be on a high HP motor. Diameter is also a factor on clearance to the cavitation plate on outboards and stern drives. You cant just pick a larger diameter prop and expect it to clear. Generally, a low pitch prop will have a larger diameter than a high pitch prop. The reason for this is that as pitch increases, blade area also increases. If the diameter also increased with pitch, then you would have way to much blade area which equals drag, so most propeller companies products will have a natural decrease in diameter as the pitch goes up for a given series of props. Putting a large diameter, high pitch prop on a lower horsepower motor is a real RPM killer. An example of this is going from a 14.5 x 17P prop on your 150hp 4 stroke to a 15.25 x 17P prop designed for a 250hp 4 stroke. The hub size is probably the same, but the blade area on the 250hp prop is going to kill your 150hp motors performance.

3: Blade count

Outboard and sterndrive props are available in everything from 2 to 7 blades or more. Many people believe that more blades just means a better prop, but this isnt the case. There are pros and cons to more or less blades, so lets break it down by blade:

- 2 blade: Built for speed. Useless on a normal outboard or sterndrive powered boat. Absolutely no pulling power down low to get the boat on the plane. Amazingly efficient at super high RPM and speeds, where most boats never go. Not an option for 99% of boats.

- 3 blade: By far the most common and efficient prop type for outboard and sterndrive powered boats. 3 blade offers the best balance between take off and top speed and gives the best fuel economy. Moderate smoothness for takeoff and cruising speeds, great smoothness at high speeds. Moderate transom lift at lower speeds. 3 blade props are the best options for boats with normal transom loads and no takeoff issues.

- 4 blade: More blades equals more bite on the water, so 4 blade props provide better bite, thrust and takeoff than a 3 blade and are much smoother at cruising speeds. Transom lift is better with a 4 blade as the extra bite & thrust wants to push the boat up in the water. This is ideal for boats with heavy motors and extra transom weight. Where the 4 blade prop falls behind the 3 blade prop is fuel economy and top speed. More blades equals more drag and this means you will have a slightly lower top speed and worse fuel economy with a 4 blade prop verses a 3 blade prop. Some boats go better with a 4 blade, some dont.

- 5, 6 and 7 blade:

These multi blade props are kind of like the 4 blade, more thrust, bite and smoothness, but at the expense of top speed and fuel economy. These are generally used on big, heavy wake boats, ski boats and displacement style hulls. They offer incredible thrust down low but top speed isnt good. Not a good choice for most planing hulls.

4: Surface area

Surface area is important, as too much creates excess drag, too little creates cavitation and slippage. Generally, most props have a standard ratio of pitch to diameter to surface area, but there are some exceptions. A low pitch, high surface area prop is used where its important that a motor attains the required RPM to make the full HP it has, but still needs a lot of bite to move a heavy boat. This is obtained by increasing the surface area. These type of props are generally fitted to smaller HP motors on houseboats, pontoons and large punts. They normally don't work very good on planing hulls. They are designed for slow speed, high weight applications.

5: Cupping

Cupping refers to the shape of a propeller blade. Its the "curl" in a prop blade towards the outside of the blades. Cupping has the effect of increasing the pitch at higher speeds. A heavily cupped prop will act like a lower pitch at slow speeds and a higher pitch at high speeds. It also helps to reduce cavitation under high loads, especially at takeoff. Most modern propellers are cupped, either with a cupped blade form, or a noticable angled lip 10-15mm in from the blade edge. Too much cupping can cause some midrange smoothness issues and also make slow speed running and turning problematic.

6: Cavitation

Cavitation is one of those things which is quite common, but hard to explain. It is effectively a pressure imbalance on the front and back of the blades of a propeller. Essentially, the imbalance cause bubbles of gas to form, which then break down as the blade passes by, which then causes the dreaded prop slip, loud growling noise and an increase in RPM from your motor. The most common times we see cavitation is when a boat is turned hard under load and the subsequent lifting of the effective prop height in the water causes cavitation. It can also occur when a motor is mounted to high on the transom or a prop with to small an amount of pitch and diameter is fitted.

7: Hub size

As outboards and stern drives increase in HP and size, so does the hub size of the lower unit. This is the diameter of the gearcase. A 250hp outboard will generally have a 4.75" hub size, whilst a 20hp will be 2.5". The hub sizing is one of the few constants between brands, with nearly every brands given HP size having the same hub size as other brands. The only time this isn't the case is where some brands offer "high thrust" models or "bigfoot" models have larger gearcases fitted to accommodate larger diameter props for high thrust, extra weight applications. When ordering a prop, you must ensure you order the correct hub size. For instance, a 4.25" hub prop for a 140hp motor may have the same spline diameter as a 4.75" hub prop for a 200hp motor, but if you were to use it, the exhaust gas leakage would result in horrific cavitation.

8: Mounting

Propellers on outboards and stern drive motors use a splined shaft for mounting. This splined shaft can vary between brands, diameter and spline count. The facilitate the mounting or your propeller and ensure it sits in the correct spot on the shaft spline, thrust washers and spacer washers are used. A retaining nut is used to retain the propeller on the spline and a retaining plate or split pin is used to stop the nut coming loose.

It is extremely important that the correct thrust washer, spacer washer, retaining nut and retaining device are used for your motor. If the incorrect hardware is used, you could up up losing your prop altogether whilst out on the water. You can also damage your gearcase if the wrong thrust washer is used, as the prop will literally grind into the gearcase flange whilst underway. When replacing your prop, you should always ensure the correct hardware for the prop is used. Here is a general rule of thumb to ensure you have the hardware correct:

- Your new prop didnt come with any hardware: If you have ordered the correct prop for your motor and it didnt come with any hardware, then that means the prop uses the same OEM hardware that came with the motor. You will need to make sure you remove the thrust washer from your existing prop after its removed, as sometimes they get stuck to the prop. The shaft splines should be cleaned and thoroughly re-greased with marine grease before sliding the thrust washer, then prop, then the spacer washer, nut washer onto the shaft, then fit the prop nut and split pin. Or, if you have a mercury style prop, you will slide the tab washer on after the spacer washer, then the nut.

- Your new prop came with hardware: Always use the hardware that comes with your new prop. Its the correct hardware for the new prop and must be used. Dont throw out your existing hardware, even if the old prop is toast. You may need it one day. The steps to fit are the same as above.

- Thrust washer fitment: The thrust washer will only fit one way. Many outboard and stern drive prop shafts have a taper on the front (boat) end of the shaft. The thrust washer will have a countersunk hole on one side. That's the way they go together, tapered shaft to countersunk hole. Some don't have a taper, but do have a ridge or step. This works the same, the spacer will have a recess to accommodate the step. If you fit your thrust washer, then slide the prop on and don't have enough thread for the nut, the thrust washer is probably on the wrong way round, or the old thrust washer is still on the shaft. If you slide the prop on and the prop flange fouls the gearcase flange, or you have too much thread on the end of the shaft, you have either forgotten the thrust washer or it could be on backwards.

- Nut tension: Your outboard owners manual may give you a torque figure when fitting your prop nut, it may not. The actual torque isnt super critical, but what is is that its tight enough to stop forward back play on the splines. If you dont have a torque figure or a torque wrench, then the best way is to fit all the hardware and prop as described above. Then get a block of soft wood like pine and use it to wedge the prop against the cavitation plate. Then firmly tighten the prop nut. It doesn't need to be super tight, you don't need a three foot bar. If the end of the prop blade is being forced into the wood, its too tight. Then back the nut off to the next slot in the castle nut, or to the next aligning lock tab on the tab washer. Then check to make sure the prop spins freely and isn't sliding back and forth on the splines. There will be up to 3mm of end play on the prop shaft, that isn't important when fitting the prop, but the prop sliding on the shaft means it isn't right.

Split pins: Always use a new split pin where possible and always....always....always use a 316G Stainless Steel split pin. Mild steel IS NO GOOD.....galvanised mild steel IS NO GOOD.....304G Stainless Steel is also NO GOOD! Always use a 316G Stainless Steel split pin. If your existing 316G Stainless Steel split pin is in good shape and straightens back out OK, you can re-use it if you have to, as 316G is quite soft and does take some serious flexing before breaking, but new is always best.

* Please remember - use the mounting hardware that came with the prop if its in the box!!!

If you cant spin the prop after its fitted - something is wrong! Remove the prop and washers and check. They may be the wrong way around.

If the prop slides back and forth on the splines after the nut is tight - something is wrong! Again, remove the prop and washers and check. They may be the wrong way around.

So just how do I select the right prop for my boat???

Prop selection is one of those things that seems to be shrouded in mystery....some sort of boating voodoo......it isnt, its pretty straight forward in reality

Our first recommendation is that if you are replacing a prop that is worn, or damaged and that prop performed correctly on your boat - replace it with the same type, diameter and pitch! There is no need to re-invent the wheel! Just reload and go again!

Now that that is out of the way, lets work through the steps to decide on the correct prop for your boat:

1 Type:

Aluminium or stainless? In the 60's and 70's, as outboards got bigger and HP increased, aluminium props got a bad reputation as they tended to flex and bend on bigger HP motors. These days, quality aluminium props like SOLAS are made of much better materials and have much more advanced heat treatment. They don't bend and flex like they did 40 years ago!

Aluminium is a good choice for smaller motors, as they are more economical to buy and also good for boats that operate in reefy and rocky areas, as they are more forgiving when they hit something. The prop absorbs a lot of the shock which can bend a prop shaft. Aluminium isn't as durable as stainless steel, so they wear a little quicker in sandy, silty water. They also lose the paint finish pretty quick in those sort of conditions. Aluminium props are much lighter than stainless steel propellers, so large horsepower motors, mainly 150hp and up, may experience some chatter when running on muffs and a slightly rougher idle when in the water as aluminium doesn't have the same weight inertia of a stainless steel prop, which is almost like having a heavier flywheel in a car. Its also the reason why many small motors don't generally get fitted with a stainless steel prop, as the extra weight can hamper acceleration as it takes more power to get the prop spinning.

Stainless steel is a great choice for motors that generally don't see a lot of rocky, reefy areas. They offer longer life and wear resistance and the extra prop weight can make for a smoother idle and low speed running on larger HP motors. There is very little difference in performance between two identically sized and shaped stainless steel and aluminium props. You generally wont see a big performance gain going from a 14x17 aluminium prop to the same shape 14x17 stainless steel prop. The motor may feel a little smoother, but that's usually it. All SOLAS stainless steel props are made from a 316G derived material. 316G marine stainless steel is ultra corrosion resistant, can be polished, is durable but also has some softness, which means it can take a beating and be repaired quite well. Some brands still sell 304G or similar props. These are generally painted as 304G stainless steel will tarnish and get surface rust in saltwater. These props have incredibly stiff and strong blades and last forever, but if you het a reef or a rock with one, it will usually mean catastrophic damage to the prop shaft and gearcase internals. We don't recommend these props unless the boat is to be used for big hours in very sandy. silty waters.

So the general rule of thumb is small motors and shallow water - aluminium, big motors and deep water - stainless steel!

2 Blades:

If you have read this far, you would have already read up on the difference between 3 and 4 blade props, but the hard and fast rule is 3 blade for allround performance and best fuel economy on light to normal weight boats and 4 blade for smooth cruising speed and better takeoff on stern heavy or just plain heavy boats, at the cost of top speed and economy.

3 Diameter:

Its covered above, but if you have now selected the right prop fitment for your outboard, right prop material, right blade amount......then dont worry about the diameter, move onto the pitch....

4 Pitch:

This is the big one, the pitch. It needs to be right, as the wrong pitch can actually hurt your motor and your back pocket. So how do you work out the correct pitch for your boat?

If the motor was fitted at a dealer, then the pitch would have already been selected to suit the boat. The dealer will generally know what prop and pitch works on that motor, when fitted to that boat. Sure, things can change after you pick up the motor or boat, such as weight changes, addition of canopies, bimini's, hard tops etc etc etc.....but we always recommend staying with a similar prop and pitch if it works on your boat!

But lets assume your existing prop is wrong. How do you select the right pitch?.......What you need to know is WOT.....WOT is king. WOT is how we know what pitch suits your boat and your boats exact circumstances. WOT doesnt lie, WOT isnt the guy at the pub who knows everything, WOT isnt that Facebook expert who may not even own a boat......WOT is wide open throttle.

WOT is how we know what pitch suits your exact boat. WOT tells you how much of your motors HP your boat is currently able to harness.

IF YOUR WOT IS TOO LOW - you may not be using all the horsepower that your motor is producing.

IF YOUR WOT TOO HIGH - you may be wasting some of the horsepower that your motor is producing.

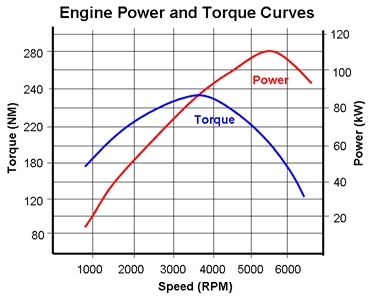

Nearly every internal combustion motor on the planet has a point in its RPM range where it makes the most power. Some motors make a broad spread of horsepower, where the peak amount is spread over a large RPM range, like a turbo powered motor or some diesels, whereas others make a sharp peak of maximum power, like a racing motor.

Just about all modern outboard and sterndrive motors on the market make their peak horsepower between 5000rpm and 6300rpm....there are very few exceptions. So how does wide open throttle affect the prop pitch you need?

Lets look at an outboard motor that is making 110hp.

Its rated at 110hp at 5800rpm. That means it makes its maximum horsepower at 5800rpm. So to put that in perspective, lets look at a simple graph below :

You can see that as RPM rises, so does the horsepower, until when it reaches 5800rpm, it starts to drop off. This is the point of peak horsepower. You can rev this motor to 6500rpm before it hits the rev limiter, but its making less horsepower at 6500rpm that it is at 5800rpm. So 5800rpm is the RPM that we want our wide open throttle (WOT remember) to be.

A motor only has as much power as it has and it can only do the most work, when it revs to the peak horsepower.

If you look at this motor at 4500rpm, its only making 100hp. So if the prop you select only allows the motor to rev to 4500rpm, you effectively now have a 100hp motor. The same goes if you have a prop that allows the motor to rev to 6500rpm....you have a motor that makes the full 110hp, but you are wasting it by revving the motor past the peak horsepower.

Propping for WOT means selecting a pitch that equates to providing the maximum boat speed right where the motor makes its maximum horsepower. Too much pitch doesnt allow that maximum horsepower to be used, not enough pitch means some of that maximum horsepower is wasted.

Lets look at what effect this means with different pitch props:

Prop 1:

14.25x19P - 110hp model fitment

- WOT with this prop is 5250RPM

- Top speed with this prop is 27 knots

Prop 2:

14.5x17P - 110hp model fitment

- WOT with this prop is 5750RPM

- Top speed with this prop is 31 knots

Prop 3:

14.75x15P - 110hp model fitment

- WOT with this prop is 6250RPM

- Top speed with this prop is 28 knots

You can see that the lower pitched prop in this case allowed the motor to rev well past peak horsepower, costing the boat speed. The higher pitched prop didnt allow the motor to rev high enough to reach peak horsepower, costing the boat speed. In this case, the 17P prop is the correct prop and will allow the motor to perform using its peak available horsepower.

So how do you check WOT on your boat to see if you have the correct prop?

Its simple. First work out what the peak HP RPM number is for your motor. If you cant find that specification or just dont know, work on 5750rpm for a modern 4 stroke, 5500rpm for a direct injection 2 stroke, 5250rpm for a carby 2 stroke and 5000rpm for a 4 stroke sterndrive.

Now take your boat out on the water, somewhere flat where you can get your boat up to top speed. Now, this is important - you cant get your boat up to top speed and WOT with the leg trimmed all the way down!!! You must use some trim so that the boat has the minimum hull in the water and the prop is aiming directly back - horizontal in the water. Trimmed all the way down will result in a RPM that is well lower than it should be. Trimmed up too high will see the prop slip and RPM to suddenly spike. The best way to do it is to bring the trim up to about a 1/4 on the gauge, or roughly having the motor vertical if you don't have a gauge. Then accelerate to full throttle. When the throttle is up to its maximum opening, check your speed, either on your gauge, GPS or phone. Then hit the trim button for a second. if your speed increases and your RPM increases, hit the button again. Keep hitting the button until the speed no longer increase, but your RPM does. This is WOT. If your WOT is more than 250-300rpm different to your peak horsepower number, then a change in pitch would be beneficial. If your WOT RPM is higher, you can go up some pitch. If its lower, you can go down some pitch.

So how much change do I make in the pitch:

The easiest way to explain this is with another example. Generally on most planing hulls with outboard or stern drive propulsion, 1 change in pitch equals around a 250rpm change in RPM. So going from a 15P prop to a 16P prop will make a 250rpm change. 15P to 17P will make around a 500rpm change.

So, if your 110hp motor, with a peak horsepower RPM figure of 5800rpm, has a WOT at maximum boat speed with a 19P of 5250rpm, a change to a 17P would theoretically make the WOT now 5750rpm, which is very close to the maximum horsepower figure. This would be worth doing to maximise the motors available horsepower.

But what if the 19P prop had a WOT at maximum boat speed of 5600rpm? Would you change the pitch? This has two answers. Generally, a difference of 150rpm in WOT is nothing and changing the prop wouldn't realise much benefit, unless the boat was having trouble with take off, in which case a change to an 18P prop would help take off and still not allow the motor to rev much past peak horsepower. But sometimes the prop manufacturers don't make a range of props in 1 pitch increments, so the next pitch down that is available might be a 17P, which would mean a theoretical WOT of 6100rpm. In this case, it would be better to stay with the existing pitch as 6100rpm is 300rpm past the peak horsepower and will see higher fuel consumption and higher cruising revs for no real benefit.

This theory is great for selecting a prop, but in the real world, it isnt always as cut and dried so it pays to know your WOT with your existing prop really well before changing the pitch.

So what other factors can determine pitch selection? We have covered WOT, boat weight....so what else?

Motor type:

Modern EFI four strokes and older carby two strokes have much different horsepower producing characteristics.

A carby two strong has strong bottom end and mid range power, that really falls away after around 5500rpm. With these type of motors, you can slightly over prop the motor (a lower WOT number compared to peak HP) as they have a wider peak horsepower range. Under propping a carby two stroke can lead to cavitation and prop slip, as the power and torque down low can overpower the prop. Slightly over propping a 2 stroke normally doesn't affect fuel consumption much.

A modern EFI four stroke and most carby 4 strokes don't make as much horsepower and torque as a carby two stroke, but make smooth, linear power right through to peak horsepower. Its better to slightly under prop a four stroke that over prop it (a higher WOT number compared to peak HP) as they don't "fall off" the power like a carby 2 stroke does. If you had a peak horsepower figure of 5700rpm for your motor, having a WOT figure of 5900rpm would be better than a prop that only allowed a WOT of 5500rpm. Loading up EFI 4 stroke motors with too much pitch just results in the motor engine management software sensing the extra load and squirting in more fuel.....which not only hurts your wallet but can also result in increased oil changes required as the engine oil gets beat up with fuel contamination and extra carbon.

What about direct injection two strokes, like ETEC's and Optimax's? We would generally recommend propping these like a 4 stroke, as they have the capacity to use a lot of extra fuel when over propped, even though they have more bottom end and midrange power than a EFI 4 stroke.

The other type of motor that can be tricky to prop is the portable, tiller handle outboard that doesnt have a RPM gauge. How do you work out WOT for a motor with no tacho? Well, its basically the same, but you are using throttle opening instead of RPM. So if you get the boat up to half throttle, but the speed doesnt increase once you open the throttle past half throttle, the motor is over propped. If you can open the throttle all the way, but the speed stops increasing past half throttle, its under propped. It can be a little tricky to fine tune your throttle opening higher in the rev range, but a marker pen can come in handy to mark the point where the boat speed stops and the throttle keeps opening. You can then check that when you stop and see how much throttle opening you are wasting (under propped) or missing (over propped). Reduce the pitch if it doesn't want to rev harder even when the throttle keeps opening, increase the pitch if it keeps revving as the throttle is opened but the boat speed stops and levels out.

Usage:

There are some certain boat usage situations where we can throw all the above over the side....they include:

- Ski and wake boats. Boats used for skiing and wakeboarding can be propped for low down pulling power and a WOT that isn't at maximum boat speed. Sometimes these boats do nothing but pull skiers, so the max boat speed requirement doesn't matter.

- Houseboats. These are generally really heavy and slow. They may use a motor that could also be used on a planing hull, but the requirement for speed isn't as important as the requirement to get that weight moving.

- Flat bottom boats and barges. Very similar to the houseboat situation, lots of load, but not a lot of speed.

- Displacement hulls. These type of hulls aren't designed to get up on the plane, so the prop required is vastly different to that used on a planing hull. The requirements are similar to the houseboats and barges, but usually with a different type of motor and prop.

- Race boats. Generally, mid to high RPM performance is the goal here and take off isnt as much of a consideration.

- Yachts. Small outboards are popular as auxillary motors for sailing boats but are propped more towards weight than speed, much like a houseboat.

Engine height:

This pertains to outboard motors only. Stern drives have a fixed outdrive height, but outboards have a height range that can be changed. This is called lowering or raising a bolt hole.

99% of the time, the motor is fitted at the boat or outboard dealer and they select the best height based on the boat type, hull deadrise, engine weight and transom style. Sometimes this goes a little wrong and when its wrong, it can effect the way a prop works.

The general rule of thumb with outboard height is that the cavitation plate, the part of the leg casting that is directly above the prop, should have the water flow when up and planing at optimum trim under the plate and not over the plate. The cav plate is designed to position the prop in the correct height below the water. If the prop is too low, it effectively puts load on the motor. if its too high, it allows prop slip and the motor will rapidly gain RPM without providing full thrust.

The motor installer will normally position the cav plate slightly below, level, or slightly above the keel. This can vary with different transoms (pod verses flat transom) and engine weights (heavy motor mounts slightly higher normally). If the motor is mounted too low, it can seem like the boat is over propped. Too high feels like not enough pitch. The way to check this is to get a passenger to have a look at the cav plate and where the water is flowing when up on the plane at mid to high speed. If there isn't ant water flowing over the cav plate, its probably the correct height. If there is water over over the cav plate, its probably too low. Its harder to tell if its too high, but one way to notice is when turning at speed....a motor mounted too high will break loose (massive prop slip and cavitation) when turning when on the plane. If your wide open throttle and prop pitch is wildly out of whack, it pays to check the motor height before trying to throw new pitch sizes at the motor.

Horsepower:

We have left the best to last......

One of the biggest misconceptions when propping and outboard or stern drive motor is that some types of props can "give you more horsepower".....

We are here to tell you that no prop sold on the planet today can give you more horsepower than what's listed on the sticker on your cowling....nope.

Generally, when people say they changed their prop and got more horsepower, they are actually telling you that their boat was over propped before and now that they have changed the pitch and the WOT figure is closer to the peak HP figure, it feels as if they have more horsepower. Well, in reality they have found more horsepower.......but it wasn't missing, it was hiding....there all along. The whole key to selecting the right propeller is to match the boat type, the usage and the available horsepower.

If your motor is over propped, you are probably leaving horsepower on the table.

If your motor is under propped, you are wasting some of your horsepower.

Its that simple. get the right prop and pitch to match your motors peak horsepower figure and you are making the most of what horsepower you have. When you get it right, your boat will have effortless takeoff, great cruising economy, of good top speed and the best fuel economy possible. Matching the prop to what you have will let you make the most of what you have. No voodoo, no magic, no trick of the week, no "the guy at the pub said".......its all about matching the prop to suit your boat.

If you are still unsure about how to choose a prop, please click here Propeller inquiry form

Please fill out all sections so we can best help you to select the correct prop for your boat.